Jacksonville's Cold Chain: A Hot Commodity

- Home

- >

- Cargo Blog

- >

- Jacksonville’s Cold Chain – A Hot Commodity

JAXPORT and its cold chain partners are building a gateway for fresh & frozen cargo.

Health-conscious dining is the latest in consumer trends according to Jeanette Mellinger, head of Uber Eats research. As the population increasingly looks for fresh food options the demand for cold storage is heating up— and Jacksonville’s cold supply chain stands ready to serve with expanded warehouse capacity, an eye on sustainability and customer-focused solutions.

Table of Contents

- Connectivity & Service

- Cold Chain Hub

- Innovation

- New or Converted Capacity

- Creative Market Model

- Longevity & Relationship Marketing

- Tech on Water

- Ongoing Growth

Story by Lori Musser

The Global Cold Chain Alliance (GCCA) is an industry organization working to promote “a universally strong cold chain where every product retains quality and safety through each link.” According to GCCA’s 2018 Customer Demand Research Report, food companies’ top two concerns are brand protection and food safety, and they see cold chain providers as indispensable to those pursuits.

JAXPORT and its cold chain partners are building a gateway where shippers moving fresh and frozen cargoes can trim days off delivery times and protect the cargo every step of the way with end-to-end supply chain temperature stability.

reefer connectivity and service

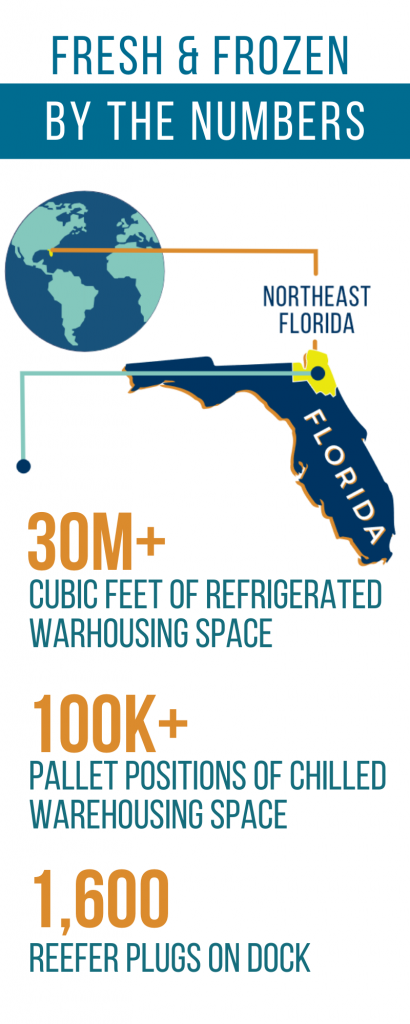

JAXPORT is well equipped for fresh and frozen cargo—with ocean carrier service to worldwide ports, more than 1,600 reefer plugs on terminals, and 30 million cubic feet of temperature-controlled warehousing with 100,000-plus pallet positions throughout the region.

“We have excellent connectivity to Asian markets, as well as to and from those in South America, Central America, the Caribbean, and Puerto Rico,” said JAXPORT’s Director of Cruise, Cargo Development, and Ro/Ro Alberto Cabrera. “Our expansive global connections provide a number of competitive options to move fresh and frozen cargo in and out of Jacksonville.”

To meet perishable shippers’ demands for speed-to-market and food chain safety, JAXPORT offers competitive turn times for both vessels and trucks, as well as outstanding intermodal connections, to reach more than 98 million U.S. consumers within a day’s drive of Jacksonville.

cold chain hub

In addition to inland and ocean carriage, cold chain services offered by port partners include order picking, freight consolidation, monitoring and tracking of reefer cargo, blast freezing, USDA inspection, and fumigation. For highly perishable goods, the industry’s flexible shipping and receiving hours are an added bonus.

Tyler Phillips, Manager, U.S. Warehouse Operations for Crowley Logistics, described the cold chain hub that has developed in Jacksonville. For Crowley, that hub is driven by its homeported fast-transit LNG-powered ships, and ‘CrowleyFresh’.

CrowleyFresh bundles individual cold-chain storage and logistics offerings into one comprehensive solution, including customs brokerage, ocean and air-freight and trucking services. Crowley’s newest cold storage facility was opened within its West 30th Street distribution center in Jacksonville last spring, bringing the company’s statewide total to 30,000 square feet of temperature-controlled and 200,000 square feet of dry warehouse space.

The new facility provides another gateway in the Southeast, said Phillips. “It’s uniquely suited as an in-transit consolidation – deconsolidation point for customers with fully perishable loads, or for those looking to combine perishable and dry loads for more economical and reliable transit,” said Phillips. The Jacksonville location services multiple trade lanes including Puerto Rico, said Phillips, while increasing the velocity of customer supply chains, decreasing total landed costs, and offering seamless and reliable collaboration among the varying components of transport.

innovation every step of the way

Scott Fernandez is Vice President of Business Development at Jacksonville’s Aqua Gulf Transport, a top shipper and logistics provider in the Puerto Rico trade. In addition to dry warehousing, Aqua Gulf’s new reefer warehouse, which opened at the end of 2018, offers a chilled section equipped with 264 pallet positions and 5,000 square feet of space, and a frozen section with another 5,000 square feet and 345 pallet racks.

“The set up maintains the cold chain from truck to warehouse through a cold dock,” Fernandez said. “State-of-the-art cold-sealed doors maintain 4,500 square feet of truck dock space at a temperature of 34 degrees.”

Aqua Gulf can receive trucks from multiple vendors, unload, store cargo of varying types and build containers consolidating loads for multiple deliveries. Fernandez said the company aims to maximize value for the customer; it can consolidate and mix cargo with different weights and sizes to utilize all the space in a container. They even have a system of temporary, reusable bulkheads that can be installed to allow two different temperature settings in one container.

new or converted capacity

Lineage Logistics, a global leader in temperature-controlled facilities, opened its second cold storage warehouse facility in Jacksonville in February 2020 to accommodate chilled and frozen products. The facility boasts an extended chilled loading dock area and touch-screen operated dock doors, among other innovative elements.

The nearly 223,000 square-foot facility will significantly expand the region’s reefer capacity, reportedly providing 36,800 new pallet positions to address strategic shifts in industry demand.

Some companies are converting facilities to better reflect the evolving frozen/fresh split. Cabrera noted that the rate of growth in demand for fresh is currently outpacing the demand for frozen capacity. Burris Logistics, for example, has moved from a 60:40 to a 50:50 split.

Related: Jacksonville-based Beaver Street Fisheries sees uptick in demand for frozen seafood during COVID-19

CREATIVE MARKET MODEL

Business models for perishables are changing. Several factors have led the cold chain industry to expand capacity for Puerto Rico. Hurricane damage, which impacted the electrical grid and limited warehouse capacity on the island, as well as electric rate impacts, resulted in shippers developing a Jacksonville just-in-time inventory model for Puerto Rico that relies on mainland reefer warehousing (inspecting, storing, racking, consolidating, etc.), and a speedy three-day transit.

“This creative market model has developed over the last few years and we have invested to meet the emerging demand,” said Fernandez. While it applies to dry and reefer business, TOTE Maritime Puerto Rico and Crowley’s fast transits and sizable reefer capacity make Jacksonville especially suitable to stage reefer cargo.

In the cold chain, having access to backup electrical is a best practice. At Aqua Gulf’s North Jacksonville location, warehousing is powered by a 62,000-square-foot solar array, comprised of 1,786 solar panels capable of generating 2.25 MW of power per day. The facilities have regular grid power, solar power, and even backup generator power. “We will not go off temperature,” said Fernandez. Maintaining cold chain integrity is important.

Efficient, effective facilities minimize loss and damage claims and attract new business. “Our quality control training employs a ‘See Something—Say Something’ policy, which is a very effective claims prevention device. Keeping customers informed is an important factor in growing our business,” Fernandez said.

LONGEVITY & RELATIONSHIP MARKETING AT AJC

Chris Swartz is Director of Global Transportation and Logistics Services for Atlanta-based AJC International, a leading global marketer of proteins. The company’s logistics arm is Jacksonville-based AJC Logistics, an independent company borne of helping customers move their product to market.

Those markets span the globe, however, the company’s roots are in Puerto Rico. “AJC has served Puerto Rico for 48 years straight, with JAXPORT as our gateway,” said Swartz. AJC has a 55,000-square foot facility for perishables, frozen goods, and ambient-temperature products in Jacksonville which largely serves Puerto Rico and the Caribbean. The company also offers nationwide trucking, ocean import and export transportation services, and other 3PL services.

“We recently expanded our cold storage footprint, which really solidifies our position as premier refrigerated provider in JAXPORT,” Swartz said.

The company specializes in consolidated mixed loads—case level items. “Customers like our array of services, and our experience,” Swartz said. “They trust us. If you are handling perishable items that is critical.”

Once a customer relationship and level of trust is established, Swartz said, AJC can help the customer defer inventory carrying costs and storage costs in Puerto Rico. “We like to say we are not in the storage business, we are in the moving cargo business.”

TECH ON WATER

TOTE’s website describes the two innovative tools: “Carrier’s NaturaLINE unit, which uses natural refrigerant CO2, can reduce carbon dioxide emissions by up to 28 percent compared to previous units using synthetic refrigerant, limiting its impact on the environment. At the same time, CoolConnect provides complete visibility of your shipment making shipping refrigerated goods even more convenient and predictable for you.” CoolConnect provides real-time monitoring for reefer containers on the road, dock or vessel. Telematic technology within the reefer boxes provides data that allows TOTE to manage and deliver time-sensitive cargo with precision and speed.

“TOTE Maritime is the first in the Jones Act trade, including Puerto Rico, to utilize NaturaLINE in our reefer fleet. This technology is a reflection of our commitment to providing our customers best in class technology while also caring for the environment,” said Jim Wagstaff, Vice President of Operations at TOTE Maritime Puerto Rico.

ONGOING GROWTH

Any development that increases capacity, provides a service that better cares for perishables, or otherwise eliminates a weak link in the supply chain for temperature controlled cargo, is a welcome advancement for shippers.

Excellent customer service, with embedded priorities that continuously improve supply chain velocity and quality control, are serving port customers well. Cultivating and serving a growing industry can be a challenge, but Northeast Florida’s cold chain continues to meet that challenge with more capacity and enhanced services.

Fernandez said that the teamwork that permeates Jacksonville’s port industry is important for perishable goods, which can’t miss a connection: “We’re finding this model we have in JAXPORT attracts customers that may have been utilizing less efficient facilities or gateways for their reefer business.”

FOR MORE INFO

Alberto Cabrera

Our convenient on-and-near dock facilities, experienced port partners and worldwide shipping service make transporting produce, refrigerated and frozen commodities @JAXPORT quick and easy. --Alberto Cabrera, JAXPORT

CLICK TO TWEET Tweet